I've been having a hard time finding literature on why we support roller coasters the way we do. I support the way I do from my experience with riding coasters and looking at pictures.

The physics and stress dynamics that accompany different styles and elements are not hard to understand. I'm having a hard time wrapping my head around why supports face inwards on over-banked turns on steel coasters. I partially understand why after thinking about the G-forces involved but for a safer bet why not Support in-line with the G-forces produced by the Roller Coaster. I often see banked turns of approximately 50-60 degrees with inward facing supports (towards the inside of the turn) - why? Why wouldn't we face those supports inline with the G-forces produced (outside)? I just can't find any literature explaining this so I was wondering how people make these choices.

Thanks for the input!

Board index ‹ Roller Coaster Games ‹ NoLimits Coaster 2 ‹ Why do we support the way we do?

Oh man. Well, in my opinion, supports make the coaster. I'm surprised better, more elaborate feedback isn't provided. I will give you some solid suggestions and feedback if you need. I know I'm new to the site but I would love helping out! I hope my first coaster post will show that I have some skill at least.

Coasterkidmwm's explanation and example make complete sense to me and that is the logic I use as well but there are situation that defy this logic in real-life coaster building. I'm not certain why.

Gouldy seems to be spot on with his comment - this is my exact thought but I see it so often used the opposite both in NL2 designs and sometimes in real life. Is there a dark-arts-coaster-support book used by big-name coaster designers?

Good question! I suppose it might have to do with varying style? Though the wooden generator allows us to select styles. I don't think I would use it, though. I thoroughly enjoy supporting my own coasters.

These are some real nice supports, cool5. I don't find anything wrong with using images as references - that's what most of us do, I would think, considering the lack of literature on the subject.

Here is a good example of where inward facing supports makes sense: If you think about the G-forces created at the peak of the turn (approximately 100-110 degree turn) would be going up and out, rather than down and out. To compensate we use the support to pull in the tracks down and in when the train rolls through. So in instances where the G-load direction exceeds (maybe) 90 degrees we should use inward facing supports to pull down the tracks rather than to hold them up.

If you think about the G-forces created at the peak of the turn (approximately 100-110 degree turn) would be going up and out, rather than down and out. To compensate we use the support to pull in the tracks down and in when the train rolls through. So in instances where the G-load direction exceeds (maybe) 90 degrees we should use inward facing supports to pull down the tracks rather than to hold them up.

I see, far too often, this technique used for style rather than function, which is OK I guess but I feel this software is inherently leaning towards realism so we should, too. Maybe that's the problem - we are using these support techniques without much consideration as to why (I know I've been guilty of that). I'm not entirely certain which is why I'm looking for feedback from everyone. Thanks for the responses so far!

Thanks for the responses so far!

Thanks for indulging my many post edits! Had an idea

Can we put together a basic-go-to-guide for supporting steel coasters? I wouldn't mind typing that up with screen shots of situations and specific elements? Perhaps we can have some professional/engineer input on this?

I actually wrote one over a decade ago.

Well, it was more of an API than a tool, but it was pretty advanced. Was used for these rides...

http://www.coastercrazy.com/7375/Red-Barchetta

http://www.coastercrazy.com/7381/Cygnus-X1

http://www.coastercrazy.com/7417/Vapor-Trails

http://www.coastercrazy.com/7435/YYZ-Round-3

http://www.coastercrazy.com/7497/Magic-Carpet-Ride

Was lost to a hard drive crash not long after.

Why do we support the way we do?

15 posts

• Page 1 of 1

What I don't get is why after 14 years of development we still don't have a steel support generator.

Reminds me of a question I've put before: g-force-versus-support-types-t35147.html

-- I was happy to be with NL1. --

Personal coaster count as of 3/2025 -- 222

"500" perhaps by the end of this year.

I will be a Thai citizen if possible in a few years.

Personal coaster count as of 3/2025 -- 222

"500" perhaps by the end of this year.

I will be a Thai citizen if possible in a few years.

I support the way I do because almost no one ever gives tips so it's easy to make the same mistakes time and time again. "These supports are mediocre" with NO elaboration might as well be just "nice" or "this sucks." It's about as much substance as those 1 word answers.

SkyArrow wrote:

I support the way I do because almost no one ever gives tips so it's easy to make the same mistakes time and time again. "These supports are mediocre" with NO elaboration might as well be just "nice" or "this sucks." It's about as much substance as those 1 word answers.

Oh man. Well, in my opinion, supports make the coaster. I'm surprised better, more elaborate feedback isn't provided. I will give you some solid suggestions and feedback if you need. I know I'm new to the site but I would love helping out! I hope my first coaster post will show that I have some skill at least.

lol240 wrote:

Reminds me of a question I've put before: g-force-versus-support-types-t35147.html

Coasterkidmwm wrote:

If you need more support because it's in a high G area or the span of track between supports is greater, thicker supports help. In the linked image I've attached, the support in the background is under a heavier G load than the support in the foreground (and the diagonal bean you see in the uh.... fore-est foreground), which is in a floaty section. They have roughly the same span of track between them and are nearly the same height but not quite. Also the single pole with the stairs around it is for the block brake (remember it's by itself, it's not an A shape and has no diagonal beams coming out of it), where not much in the way of G's is happening and you can compare its thickness as well.

I'm not an engineer though they'll know better. This has to be loaded with situation-related exceptions (earthquakes, supports dodging something, etc). Hope this helps.

I'm not an engineer though they'll know better. This has to be loaded with situation-related exceptions (earthquakes, supports dodging something, etc). Hope this helps.

gouldy wrote:

Steel loves tension. Steel is all over it when it comes to tension. That's pretty much of the basis of suspension bridges, of course. Steel is still good at dealing with compression, just not as good as it is at dealing with tension.

What's not great at dealing with tension, though, is where the support is bolted to the floor - that component is FAR better at dealing with compression than tension. You'll tend to see support structure is set in the direction of compression wherever possible, because I would imagine that slightly more supports may be required for support structure under tension, purely because of the extra required anchor points with the floor or other nearby structures.

What's not great at dealing with tension, though, is where the support is bolted to the floor - that component is FAR better at dealing with compression than tension. You'll tend to see support structure is set in the direction of compression wherever possible, because I would imagine that slightly more supports may be required for support structure under tension, purely because of the extra required anchor points with the floor or other nearby structures.

Coasterkidmwm's explanation and example make complete sense to me and that is the logic I use as well but there are situation that defy this logic in real-life coaster building. I'm not certain why.

Gouldy seems to be spot on with his comment - this is my exact thought but I see it so often used the opposite both in NL2 designs and sometimes in real life. Is there a dark-arts-coaster-support book used by big-name coaster designers?

Mikey wrote:

What I don't get is why after 14 years of development we still don't have a steel support generator.

Good question! I suppose it might have to do with varying style? Though the wooden generator allows us to select styles. I don't think I would use it, though. I thoroughly enjoy supporting my own coasters.

cool5 wrote:

I support based on rcdb pictures.

Like the pics of this Meisho Coaster I try to support the same way for my coaster in NL2.

Like the pics of this Meisho Coaster I try to support the same way for my coaster in NL2.

These are some real nice supports, cool5. I don't find anything wrong with using images as references - that's what most of us do, I would think, considering the lack of literature on the subject.

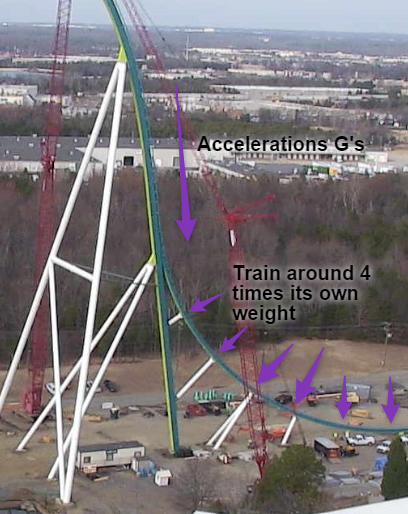

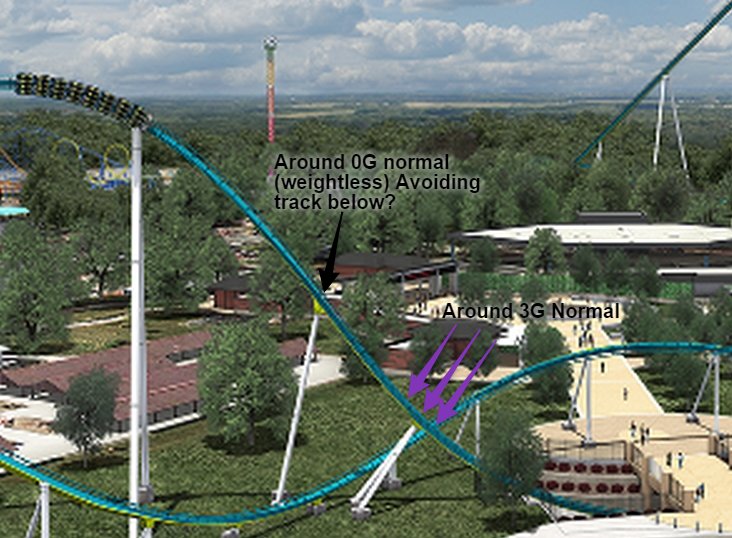

Here is a good example of where inward facing supports makes sense:

If you think about the G-forces created at the peak of the turn (approximately 100-110 degree turn) would be going up and out, rather than down and out. To compensate we use the support to pull in the tracks down and in when the train rolls through. So in instances where the G-load direction exceeds (maybe) 90 degrees we should use inward facing supports to pull down the tracks rather than to hold them up.

If you think about the G-forces created at the peak of the turn (approximately 100-110 degree turn) would be going up and out, rather than down and out. To compensate we use the support to pull in the tracks down and in when the train rolls through. So in instances where the G-load direction exceeds (maybe) 90 degrees we should use inward facing supports to pull down the tracks rather than to hold them up. I see, far too often, this technique used for style rather than function, which is OK I guess but I feel this software is inherently leaning towards realism so we should, too. Maybe that's the problem - we are using these support techniques without much consideration as to why (I know I've been guilty of that). I'm not entirely certain which is why I'm looking for feedback from everyone.

Thanks for indulging my many post edits! Had an idea

Can we put together a basic-go-to-guide for supporting steel coasters? I wouldn't mind typing that up with screen shots of situations and specific elements? Perhaps we can have some professional/engineer input on this?

I was going to go into detail about the whole tensile strength vs compressive strength, but it seems Gouldy already beat me. Another point to add, however, is whether the force channels down into the footer, or instead pulls it out of the ground.

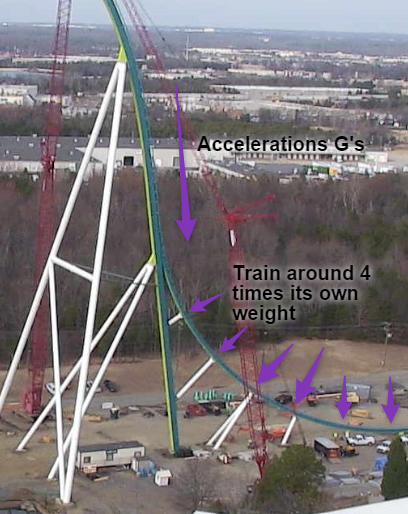

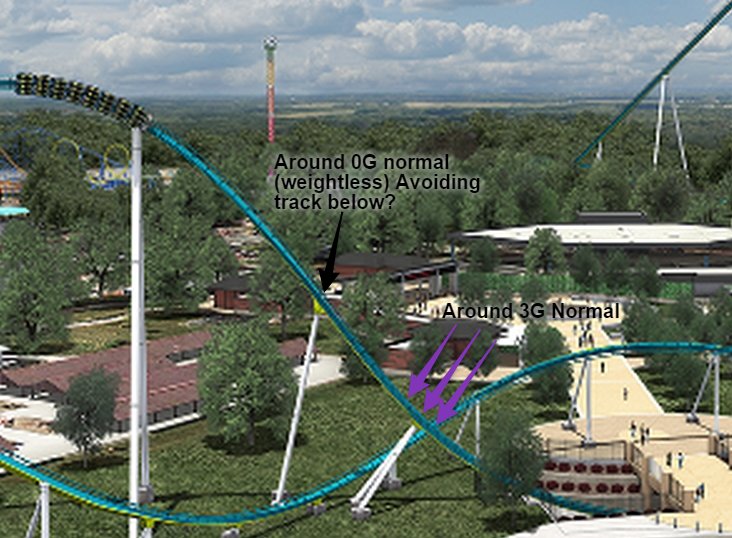

With regards to the G forces experienced on the train, you have to remember how the forces are being applied. In the train, the positive force is pushing you down into your seat. So for a support, this same force is acting perpendicular to the track, which is where the support aims directly into.

A supports role is simply to hold the track up, yet also brace against the forces when the train goes over the track. At 4 G's the train is 4 times its normal weight, so a diagonal brace helps. At the same time, to keep costs down, I believe that supports aim to use as little steel as realistically possibly.

Negative accelerations G forces:

Positive accel and high positive normals:

The arrows show the direction of the forces, remember that normal G's push you into your seat, and accel push you into the back of it. These supports brace mainly against those normals, while all together with the inward arc of the track combine to hold the track up. On their own, the supports are weak, but combined with each other and the circle shape of the track, they are strong.

The inward push of the G forces against the extended lift spine could arguably weaken the structural integrity of the lift spine. Yet the largest A frame and the support beneath it are leaning against this, to counteract.

With regards to the G forces experienced on the train, you have to remember how the forces are being applied. In the train, the positive force is pushing you down into your seat. So for a support, this same force is acting perpendicular to the track, which is where the support aims directly into.

A supports role is simply to hold the track up, yet also brace against the forces when the train goes over the track. At 4 G's the train is 4 times its normal weight, so a diagonal brace helps. At the same time, to keep costs down, I believe that supports aim to use as little steel as realistically possibly.

Negative accelerations G forces:

Positive accel and high positive normals:

The arrows show the direction of the forces, remember that normal G's push you into your seat, and accel push you into the back of it. These supports brace mainly against those normals, while all together with the inward arc of the track combine to hold the track up. On their own, the supports are weak, but combined with each other and the circle shape of the track, they are strong.

The inward push of the G forces against the extended lift spine could arguably weaken the structural integrity of the lift spine. Yet the largest A frame and the support beneath it are leaning against this, to counteract.

TheArchitect,

Beautiful right up!

This is great! I'm not certain why I didn't think about the forces moving down the track. Here I was thinking of the train hitting that hill and exerting force forward (towards the hill) and that a support would be beneficial facing the other way but this makes more sense. I will have to look at my current coaster (Dragonfly) when I get home to see how I have it set.

This is my thought exactly.

I find that, for the most part, using the G-Force comb is a huge asset when supporting but as soon as that comb rises beyond 60-70 degrees we have to start thinking about saving steel and lateral forces on the support itself (more steel=more weight). Also we can't have a lateral brace shooting out a couple hundred feet as it's not practical or beneficial. I don't think I'm overthinking it but I do think I'm not explaining it well. Screenshots to come later. Everything that has been said so far is on-point! Love that I'm not actually crazy because I obsess over supporting my coasters properly (until we have a stress comb, of course). A stress comb would be HUGELY beneficial in supporting our coasters, but it would remove the dark-magic-effect of good supporting!

Here is an example from my most recent coaster, Dragonfly, that has a slight over-banked turn. As you can see the G-force comb is just over 90 degrees. My decision to use exterior lateral supports seemed appropriate. In this situation perhaps they can go either way. Thoughts?

Beautiful right up!

TheArchitect wrote:

Negative accelerations G forces:

This is great! I'm not certain why I didn't think about the forces moving down the track. Here I was thinking of the train hitting that hill and exerting force forward (towards the hill) and that a support would be beneficial facing the other way but this makes more sense. I will have to look at my current coaster (Dragonfly) when I get home to see how I have it set.

TheArchitect wrote:

With regards to the G forces experienced on the train, you have to remember how the forces are being applied. In the train, the positive force is pushing you down into your seat. So for a support, this same force is acting perpendicular to the track, which is where the support aims directly into.

This is my thought exactly.

I find that, for the most part, using the G-Force comb is a huge asset when supporting but as soon as that comb rises beyond 60-70 degrees we have to start thinking about saving steel and lateral forces on the support itself (more steel=more weight). Also we can't have a lateral brace shooting out a couple hundred feet as it's not practical or beneficial. I don't think I'm overthinking it but I do think I'm not explaining it well. Screenshots to come later. Everything that has been said so far is on-point! Love that I'm not actually crazy because I obsess over supporting my coasters properly (until we have a stress comb, of course). A stress comb would be HUGELY beneficial in supporting our coasters, but it would remove the dark-magic-effect of good supporting!

Here is an example from my most recent coaster, Dragonfly, that has a slight over-banked turn. As you can see the G-force comb is just over 90 degrees. My decision to use exterior lateral supports seemed appropriate. In this situation perhaps they can go either way. Thoughts?

To reinforce TheArchitect's post, this diagonal beam keeps the entire station from violently shaking when the train stops hard in the station. It also collects vomit if someone ralphs in rows 5 or 6 and smells ALL DAY until someone gets it with the hose. Every single place on Rougarou where the train stops except the block brake/MCBR has one of those diagonal beams facing the same direction that TheArchitect posted.

Link in case embedding fails:

http://i102.photobucket.com/albums/m93/ ... ywqnok.jpg

I305 has their variant of this as well:

One should not forget the useless-looking thin single pole with no bracing holding up the peak on B&M inverts (where the forces are around zero).

Link in case embedding fails:

http://i102.photobucket.com/albums/m93/ ... ywqnok.jpg

I305 has their variant of this as well:

One should not forget the useless-looking thin single pole with no bracing holding up the peak on B&M inverts (where the forces are around zero).

"Careful man, there's a beverage here!"

^ It's also the one of a few places where there is a long standing static load and when in operation a very dynamic load. When guest board there is a lateral and vertical load. During advance train operation there is horizontal load as the feed motors pull the train from the same mounts the train is sitting on. Flex in this area would be bad as it messes with the feed motor alignments.

Mikey wrote:

What I don't get is why after 14 years of development we still don't have a steel support generator.

I actually wrote one over a decade ago.

Well, it was more of an API than a tool, but it was pretty advanced. Was used for these rides...

http://www.coastercrazy.com/7375/Red-Barchetta

http://www.coastercrazy.com/7381/Cygnus-X1

http://www.coastercrazy.com/7417/Vapor-Trails

http://www.coastercrazy.com/7435/YYZ-Round-3

http://www.coastercrazy.com/7497/Magic-Carpet-Ride

Was lost to a hard drive crash not long after.

There currently is a steel support generator, but it's extremely limited . Fortunately last I heard geforcefan on NLE was working on a really sophisticated V2 of the program, and from what he's shown it's very impressive

^Have to admit it looks really fantastic. The supports on those rides are pretty advanced for a program/api. I only wish it was still available, i'd take it in a heartbeat

^Have to admit it looks really fantastic. The supports on those rides are pretty advanced for a program/api. I only wish it was still available, i'd take it in a heartbeat

This thread should never die, so more supporting technique examples to discuss are needed!

-- I was happy to be with NL1. --

Personal coaster count as of 3/2025 -- 222

"500" perhaps by the end of this year.

I will be a Thai citizen if possible in a few years.

Personal coaster count as of 3/2025 -- 222

"500" perhaps by the end of this year.

I will be a Thai citizen if possible in a few years.

i was gunna be working on a series of tutorials, so you guys may see that in the near future

Head Moderator

Director, Structural Engineer - PEAK Amusements

Site Contest Judge (Supporting)

Chatroom Admin

Director, Structural Engineer - PEAK Amusements

Site Contest Judge (Supporting)

Chatroom Admin

Brake runs usually have slip joints from the rest of the track, so that may have something to do with the support being placed against the grain instead of with.

15 posts

• Page 1 of 1

-

- Related topics

- Replies

- Views

- Last post

-

- [NL2] Support Scenery

1, 2, 3 by Turbo » June 10th, 2014, 5:30 pm

by Turbo » June 10th, 2014, 5:30 pm

- 60 Replies

- 17760 Views

- Last post by iidarkdeception

February 12th, 2017, 9:08 am

- [NL2] Support Scenery

-

- Support fence problem

by plantoris » July 11th, 2014, 10:48 pm - 11 Replies

- 2601 Views

- Last post by tiepilot35

October 11th, 2014, 4:41 pm

- Support fence problem

-

- NL2 - Multiplayer Support Petition

by mrcrolly » June 5th, 2015, 10:03 am - 7 Replies

- 2068 Views

- Last post by TTD03

June 12th, 2015, 8:30 pm

- NL2 - Multiplayer Support Petition

-

- Sharing Support Footers and Realism

by zacattack1104 » February 21st, 2014, 2:24 pm - 5 Replies

- 1818 Views

- Last post by BoboMunkee

February 21st, 2014, 10:24 pm

- Sharing Support Footers and Realism

-

- G-Force versus Support Types.

by lol240 » April 13th, 2015, 8:06 am - 11 Replies

- 3313 Views

- Last post by mkingy

May 19th, 2015, 8:53 am

- G-Force versus Support Types.